What Quality Control Testing Actually Does in Manufacturing

Quality control testing isn’t just about checking finished products. It’s about catching problems before they happen. In manufacturing, a single defective part can mean wasted materials, delayed shipments, or worse - a recalled product that damages trust. The goal isn’t to find mistakes after they’re made. It’s to stop them from ever reaching the next stage. This isn’t guesswork. It’s a repeatable system built on data, standards, and trained people.

Back in the 1920s, Walter Shewhart at Bell Labs started using statistical methods to track variation in production. That idea grew into what we now call quality control. W. Edwards Deming later pushed the shift from inspecting the end product to fixing the process. Today, that’s still the rule. If you’re only testing at the end, you’re already too late. Companies that do this right cut scrap and rework costs by over 30%, according to the American Society for Quality. That’s not a small win. That’s profit.

Step 1: Define Clear Quality Standards

You can’t test for something if you don’t know what you’re looking for. Every product needs documented specs. Not vague descriptions like “looks good” or “works fine.” Real numbers. For example, a machined metal part might need a surface roughness of Ra 1.6 μm. Too rough? It won’t seal properly. Too smooth? It might wear out faster. These tolerances are set based on function, not convenience.

In electronics, color consistency matters. A circuit board’s solder mask can’t vary by more than ΔE < 2.0 on the CIELAB scale - that’s the difference between a slightly off-green and a visibly wrong one. In pharmaceuticals, the chemical composition of a tablet must match its formula within strict limits, verified by spectrographic analysis per ASTM E415. These aren’t suggestions. They’re requirements tied to safety, performance, or compliance.

Standards also come from industry rules. Electronics follow IPC-A-610 for visual inspection. Medical devices follow ISO 13485. Food and pharma follow FDA 21 CFR Part 211. If you don’t know your standard, you can’t test to it. And if you can’t test to it, you’re flying blind.

Step 2: Choose the Right Inspection Methods

Not every test fits every product. You wouldn’t use a caliper to check the purity of a drug. And you wouldn’t run a chemical assay on a plastic housing. The method has to match the risk.

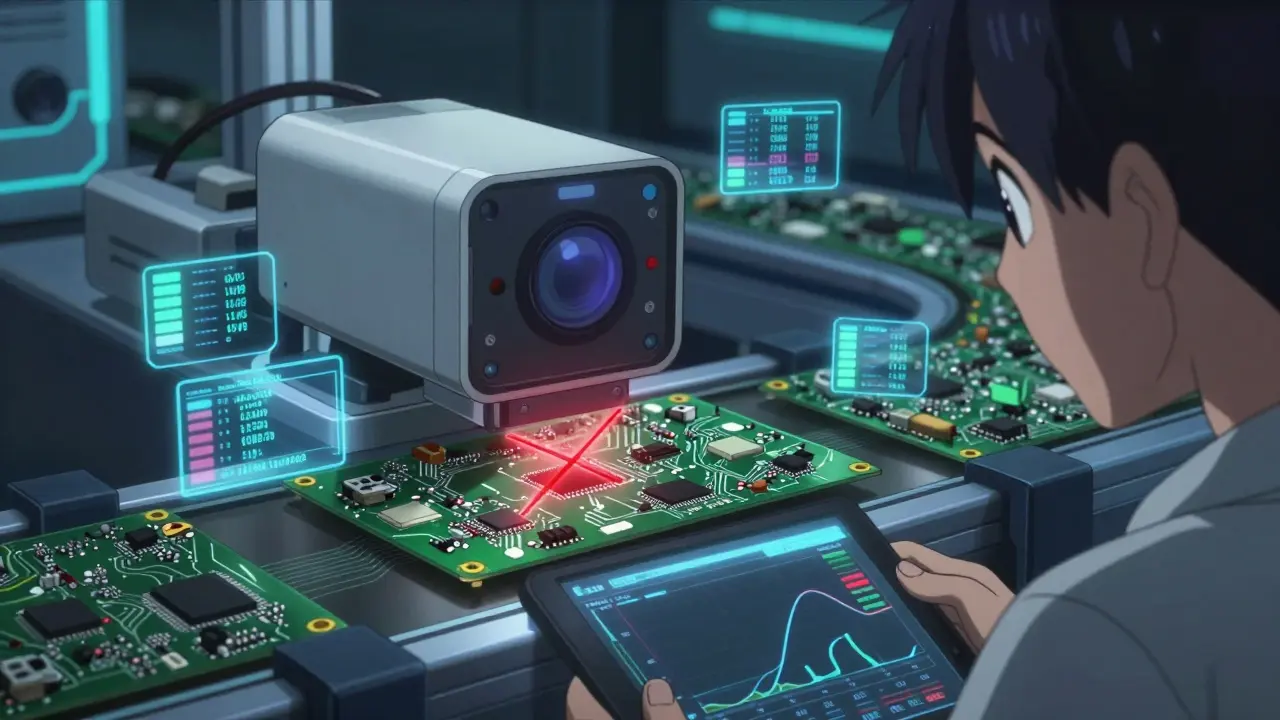

For dimensional checks, you might use digital calipers, micrometers, or laser scanners. For electrical components, you test resistance, voltage, and continuity with multimeters or automated test equipment. For surface defects, vision systems with AI are now common - they spot scratches, dents, or missing labels faster than a human eye. In high-volume production, automated probing systems are replacing manual checks. One manufacturer saw defect escape rates drop by 63% after switching from end-of-line inspections to real-time in-process monitoring.

Sampling matters too. You don’t test every single item unless it’s a life-critical part like a pacemaker. For most products, you use AQL (Acceptable Quality Level) sampling. MIL-STD-105E says you can sample 50 units from a batch of 10,000 and accept the whole lot if only one has a major defect. But if you’re making medical devices, you might do 100% inspection. The key is matching the method to the risk.

Step 3: Train Your Team Properly

Tools don’t fix quality. People do. And if your operators aren’t trained, even the best equipment won’t help. Training isn’t a one-hour safety video. It’s hands-on, role-specific, and repeated. A quality inspector needs to know how to use a CMM (coordinate measuring machine), interpret an X-bar chart, and document a deviation. A line worker needs to know when to stop the line if something looks off.

ASQ reports that 68% of manufacturing facilities struggle with inconsistent operator adherence. Why? Poor training. Effective programs require 16 to 40 hours of specialized training, depending on the role. Certification is key. Target 95%+ proficiency. Track it. Re-test every six months. And don’t forget to train supervisors. They’re the ones who decide whether to override a process or escalate an issue.

Dr. David Schwinn, an ASQ Fellow, says the best systems combine human observation with machine data. A sensor might flag a temperature spike, but a trained operator knows if it’s a real problem or just a momentary glitch. That’s the sweet spot.

Step 4: Monitor Processes in Real Time

Waiting until the end of the line to find a problem is like checking your car’s oil after it’s already seized. Real-time monitoring changes everything.

Modern factories use IoT sensors to track temperature, pressure, vibration, and cycle time. That data feeds into software like Minitab or JMP, which plots control charts. If a process moves outside its 3σ control limits, the system alerts the team immediately. This is statistical process control - not magic, just math applied consistently.

Capability indices like Cp and Cpk tell you if your process is actually capable of meeting specs. A Cpk above 1.33 means your process is centered and tight enough to produce good parts consistently. Below that? You’re rolling the dice. One electronics manufacturer in Perth reduced variation by 40% in six months just by monitoring Cpk daily and adjusting machine settings before defects occurred.

Don’t collect data just to collect it. Use it to react. If your X-bar chart shows a slow drift in part length over 100 units, fix the tooling before the 101st unit is made. That’s prevention. That’s quality control.

Step 5: Analyze Results and Spot Trends

Testing gives you data. Analysis gives you insight. Many companies test heavily but never look at the bigger picture. They see a few defective units and just scrap them. They don’t ask: Why did these happen? Are they random? Or is there a pattern?

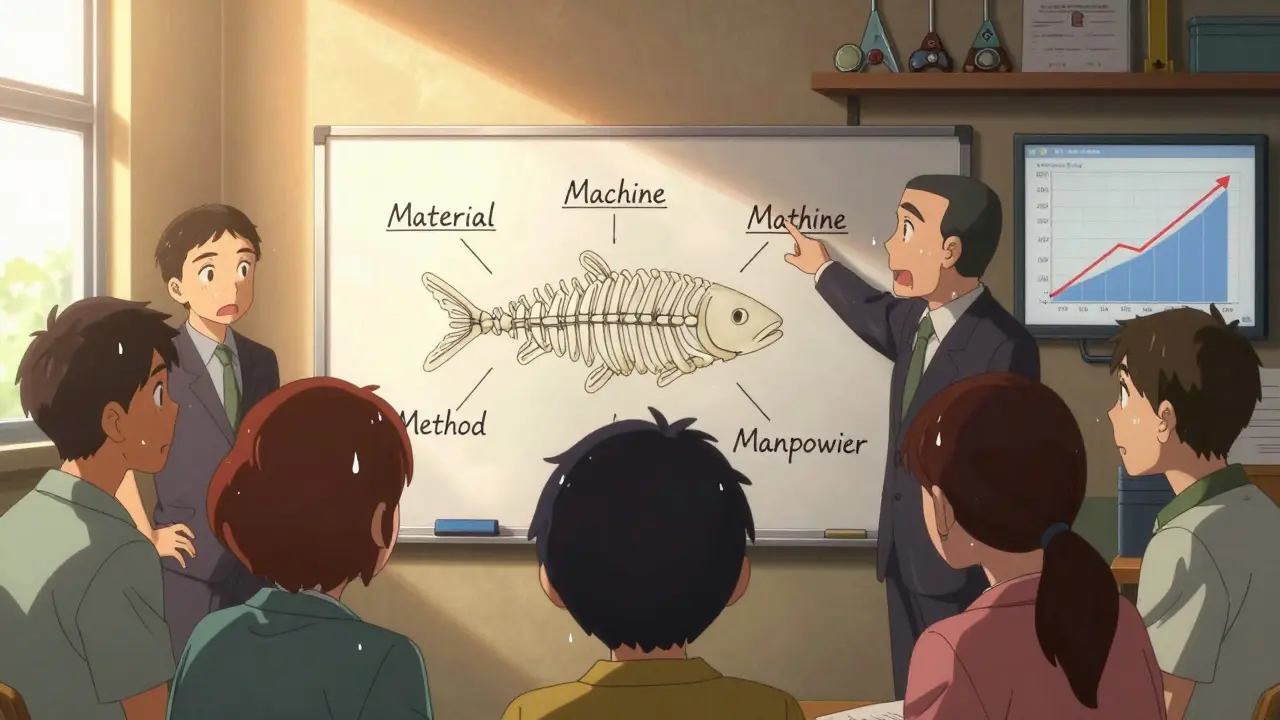

Use Pareto charts to find the top 20% of defects causing 80% of the problems. Use fishbone diagrams to trace causes back to machine, material, method, or operator. Look at trends over time. Is the defect rate climbing every Monday? Maybe the night shift isn’t calibrating tools properly. Is a specific batch always failing? Maybe the raw material supplier changed.

One pharmaceutical company found that 43% of FDA Form 483 observations in 2021 were due to unvalidated test methods. That means they were using tools or procedures that hadn’t been proven to work. They fixed it by validating every test before use - and documenting every step. Now, their inspection results are trusted by regulators.

Don’t just report numbers. Explain them. What changed? What worked? What didn’t? This turns QC from a cost center into a source of continuous improvement.

Step 6: Take Corrective Action - and Prevent It Again

Fixing a defect once isn’t enough. You have to fix the root cause. That’s CAPA - Corrective and Preventive Action. It’s not a form to fill out. It’s a process.

When a defect is found, you investigate. You don’t just replace the part. You ask: Why did this happen? Was it a bad batch of material? A misaligned machine? A skipped step in the checklist? Then you fix the system. Maybe you update the work instruction. Maybe you add a second verification step. Maybe you recalibrate the machine every four hours instead of eight.

Regulators require this. The FDA wants root cause analysis done within 72 hours. ISO 9001:2015 demands it. And companies that do it well see fewer repeat issues. One automotive supplier cut warranty claims by 50% in two years by implementing structured CAPA. They didn’t just fix parts. They fixed their process.

Documentation is non-negotiable. Use bound logbooks or electronic systems with audit trails (21 CFR Part 11 compliant for pharma). Every action, every decision, every change must be recorded. Not for show. For proof. If an inspector shows up, you need to show you knew, you acted, and you learned.

What’s Changing in Quality Control Right Now

Technology is changing how QC works. AI-powered visual inspection systems are now used by 37% of Fortune 500 manufacturers - up from just 12% in 2020. These systems can spot defects invisible to the human eye, like micro-cracks in circuit boards or tiny contamination spots on medical devices.

Digital twins - virtual copies of physical production lines - are letting manufacturers simulate quality issues before they happen. Boeing cut assembly defects by 31% using this method. Augmented reality glasses are guiding inspectors through complex checks, improving accuracy by 22% in Toyota’s pilot programs.

But here’s the catch: technology doesn’t replace quality culture. It enhances it. As Dr. Michael Porter wrote in 2023, the most resilient systems still follow Deming’s old rules: focus on process, involve people, use data, and never stop improving. The tools are new. The principles aren’t.

Regulations are tightening too. The EU’s Medical Device Regulation and the FDA’s new Quality Management Maturity initiative are looking beyond paperwork. They’re asking: Do you have a quality mindset? Do your people care? Is quality built into every decision? That’s the next level.

How Much Does Quality Control Cost - and Is It Worth It?

Manufacturers spend 3.2% to 5.8% of their revenue on quality control. Automotive companies spend the most - nearly 6% - because their stakes are higher. Consumer goods spend less, but they pay the price in returns if they cut corners.

Here’s the math: A company that spends 4% of revenue on QC saves 12% in scrap, rework, and recalls. That’s a 200% return. The ASQ says companies with strong QC systems reduce waste by over 30%. That’s not an expense. It’s a multiplier.

And the market agrees. The global QC testing industry is worth $12.7 billion and growing at 6.3% a year. North America and Europe have adoption rates over 90%. Asia is catching up. The question isn’t whether you can afford QC. It’s whether you can afford not to have it.

Final Thought: Quality Is a Habit, Not a Step

Quality control isn’t a department. It’s a mindset. It’s not something you do at the end of the line. It’s something you do every hour, every shift, every day. It’s training your team to speak up. It’s trusting data over gut feeling. It’s fixing the system, not just the symptom.

If you’re starting from scratch, don’t try to do everything at once. Pick one high-risk product. Define clear specs. Train your team. Monitor one key parameter. Analyze the results. Fix the root cause. Do it again. Build the habit. Then expand.

Because in manufacturing, the only thing worse than a defective product is thinking you’ve fixed it - when you haven’t fixed the reason it happened at all.

Radhika M

December 16, 2025 AT 19:25Really clear breakdown. I work in a small factory in India and we just started using AQL sampling last month. Already saw fewer returns from customers. Simple stuff works if you stick to it.

Philippa Skiadopoulou

December 17, 2025 AT 00:50Statistical process control remains the cornerstone of industrial quality. The reliance on human intuition over data remains a systemic flaw in many operations.

Pawan Chaudhary

December 18, 2025 AT 08:47This is awesome! We’re just starting out with QC in our shop and this feels like a roadmap. No jargon, just real talk. Keep it coming!

Jonathan Morris

December 19, 2025 AT 02:33They never mention how 70% of ‘quality control’ is just corporate theater. The real goal is to avoid liability, not improve products. CAPA forms are just legal shields. The machines still break. The suppliers still cheat. The audits are scripted.

Linda Caldwell

December 19, 2025 AT 16:39YES. This is the energy we need. Stop treating QC like a box to check. It’s the heartbeat of your brand. Train your people. Trust the data. Fix the system. Do it again tomorrow. That’s how you win.

Anna Giakoumakatou

December 20, 2025 AT 21:45Oh wow. A 12-page LinkedIn post dressed up as a whitepaper. Did you also include a pie chart showing how ‘quality culture’ increases dopamine levels in middle managers? Bravo. Truly profound.

CAROL MUTISO

December 21, 2025 AT 15:34There’s something quietly beautiful about the way quality control turns chaos into rhythm. You don’t just inspect-you listen. The machine hums differently when the bearing’s wearing out. The solder joint glows faintly wrong under UV. The operator hesitates before hitting ‘start.’ These aren’t defects. They’re whispers. And the best teams? They lean in.

I’ve seen factories where QC was a burden. And others where it was sacred. The difference isn’t software or sensors. It’s whether the person holding the caliper feels like they’re protecting something real.

That’s the invisible thread. The one that connects Walter Shewhart’s charts to the kid in Bangladesh learning to spot a micro-crack with a loupe. It’s not about compliance. It’s about care.

Erik J

December 21, 2025 AT 16:28Is there data on how often real-time monitoring systems generate false positives? I’ve seen teams overwhelmed by alerts that turned out to be sensor drift. Maybe the focus should shift from more data to better signal filtering.

Martin Spedding

December 23, 2025 AT 01:29lol they said ‘statistical process control’ like its magic. My cousin works at a plant and they just turn off the alarms so they dont get yelled at. 100% inspection? More like 10% and pretend the rest are fine.

Donna Packard

December 24, 2025 AT 14:32This reminded me of my first job on the line. We didn’t have fancy sensors. Just a supervisor who’d stop the belt and say, ‘That doesn’t look right.’ We fixed more problems that way than any audit ever did.