Material stiffness is a mechanical property that describes a material's resistance to deformation under load, typically quantified by the elastic modulus (Young's modulus). Higher stiffness means less deflection, which can translate into lighter structures, longer service life, and different environmental footprints.

Why Stiffness Matters for Sustainability

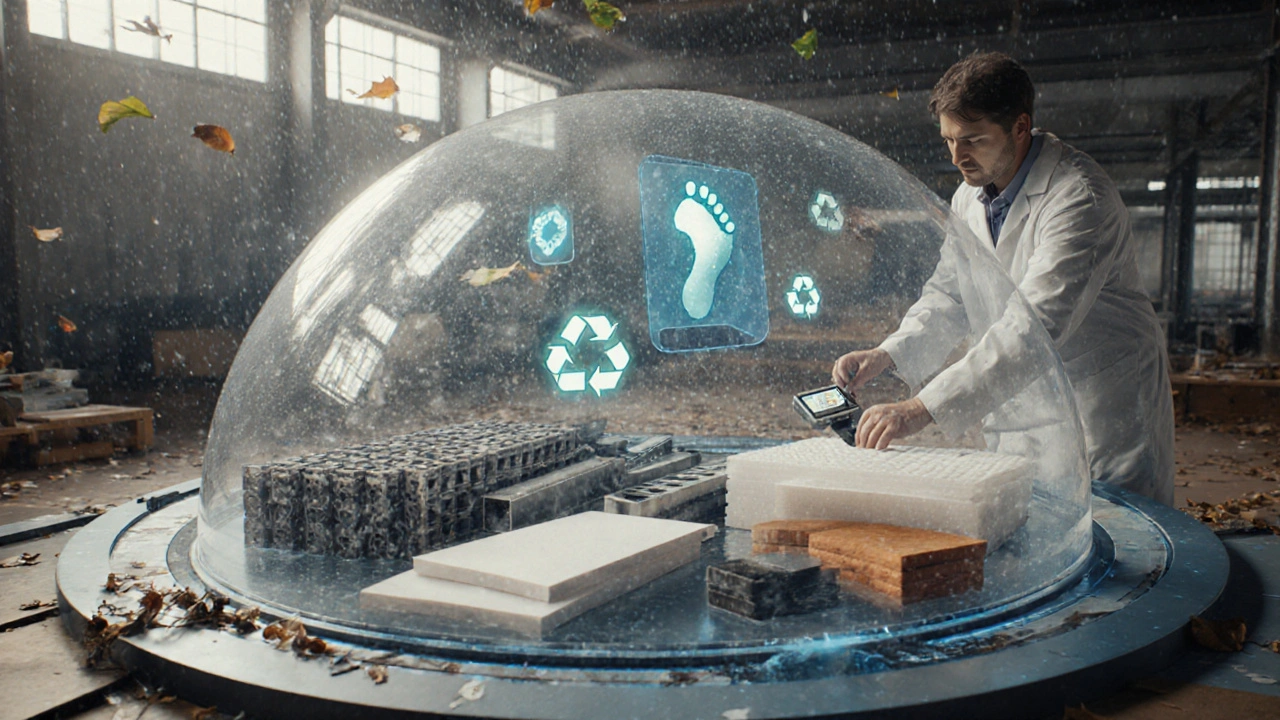

Designers often chase high stiffness to meet performance specs-think aerospace wings or automotive chassis. But stiffness also dictates how much material you need, the energy spent shaping it, and how easy it is to recycle later. In a circular economy, every kilogram saved or reused cuts carbon emissions. So understanding the link between stiffness and the environment is key for truly sustainable material choices.

Elastic modulus is a measure of material stiffness expressed in gigapascals (GPa). For example, steel has an elastic modulus around 200GPa, while polypropylene sits near 1.5GPa. This numeric value directly impacts design decisions and, by extension, environmental outcomes.

Stiffness, Energy Use, and Carbon Footprint

Manufacturing energy consumption correlates with how much a material must be processed to achieve the desired stiffness. High‑stiffness metals often require intensive alloying, heat‑treatment, and precision machining, each step adding megajoules of energy per kilogram. In contrast, polymer composites can achieve comparable stiffness with less processing, but their raw‑material extraction may involve petrochemical emissions.

According to a 2023 life‑cycle assessment (LCA) by the International Energy Agency, producing 1kg of high‑strength steel emits roughly 2.2kgCO₂e, while 1kg of carbon‑fiber‑reinforced polymer (CFRP) emits about 12kgCO₂e. However, CFRP's superior stiffness‑to‑weight ratio can lead to lighter vehicles, offsetting the upfront carbon hit over the product’s use phase.

Life cycle assessment is a cradle‑to‑grave analytical method that quantifies environmental impacts-energy use, emissions, waste-across a product’s lifespan. It helps engineers compare whether a high‑stiffness material truly delivers net sustainability gains.

Recyclability and End‑of‑Life Scenarios

Stiffness influences how easy a material is to sort, shred, and reclaim. Metals are inherently recyclable; their stiffness does not hinder recycling streams. Polymers, especially thermosets used for high‑stiffness applications, often cannot be remelted, ending up in landfill or requiring energy‑intensive chemical recycling.

Recycling rates vary widely: steel recycling reaches ~85% globally, while CFRP recycling sits below 10% due to limited infrastructure. The challenge is to develop recyclable high‑stiffness alternatives-bio‑based composites, recyclable thermoplastic composites, or advanced alloy designs.

Recycling rate is a percentage of material reclaimed and re‑entered into production after its first use. High stiffness materials with low recycling rates can lock carbon into the waste stream, undermining sustainability goals.

Composite Materials: Bridging Stiffness and Sustainability

Composite materials combine a stiff reinforcement (fibers) with a lighter matrix (resin). By tailoring fiber orientation, designers can achieve targeted stiffness with minimal material. This approach often reduces overall weight, leading to lower operational emissions-for instance, aircraft using carbon‑fiber composites can cut fuel consumption by 20%.

Yet, the sustainability profile hinges on the matrix choice. Thermoplastic composites (e.g., PEKK, PA‑6) are recyclable, while traditional epoxy thermosets are not. Selecting a recyclable matrix while maintaining required stiffness is the sweet spot for circular‑economy design.

Composite materials are engineered combinations of two or more distinct phases, typically fibers and a polymer matrix, delivering superior stiffness‑to‑weight ratios. Their environmental performance depends on both fiber type and matrix recyclability.

Comparing High‑Stiffness vs. Low‑Stiffness Materials

| Attribute | High‑Stiffness Materials | Low‑Stiffness Materials |

|---|---|---|

| Elastic Modulus (GPa) | 150‑200 (e.g., steel, carbon fiber) | 0.5‑3 (e.g., polypropylene, PVC) |

| Manufacturing Energy (MJ/kg) | 30‑45 (high‑temperature processes) | 5‑12 (injection molding, extrusion) |

| Carbon Footprint (kgCO₂e/kg) | 2‑12 (depending on alloy/composite) | 0.8‑2.5 (common polymers) |

| Recyclability (%) | 80‑90 (metals) / 5‑15 (thermoset composites) | 70‑95 (thermoplastics) |

| Typical Use | Structural frames, aerospace, high‑performance gear | Packaging, consumer housings, flexible components |

The table shows that high stiffness can lead to higher upfront energy use and carbon emissions, but it may enable lighter designs that offset those impacts during use. Low‑stiffness materials are easier to recycle and consume less energy to produce, yet they often require more material mass to meet performance, which can increase waste.

Integrating Stiffness into Circular‑Economy Strategies

Design for circularity means planning for reuse, refurbishment, and recycling from day one. Engineers can adopt the following practices:

- Choose recyclable high‑stiffness matrices (e.g., thermoplastic carbon‑fiber composites) to retain stiffness while keeping end‑of‑life pathways open.

- Optimize component geometry so that stiffness is achieved with minimal material-use finite‑element analysis to identify stress‑critical zones.

- Implement modular design; stiff structural modules can be detached, refurbished, and re‑integrated, extending product life.

- Collaborate with recyclers to develop closed‑loop supply chains for specific high‑stiffness alloys or composites.

Circular economy is a systemic approach that keeps resources in use for as long as possible, extracting maximum value before recovery and regeneration. Stiffness decisions must align with these loops to avoid “design‑for‑obsolescence”.

Case Study: Sustainable Bicycle Frames

Traditional bike frames use steel (elastic modulus ~200GPa) or aluminum (≈70GPa). Both are highly recyclable, but they add weight. A 2022 pilot in Melbourne swapped steel for a recyclable thermoplastic carbon‑fiber composite (elastic modulus ~150GPa). Manufacturing energy rose 20% because of fiber processing, but the frame weight dropped 30%, leading to a 15% reduction in rider‑energy consumption over 10,000km of use. End‑of‑life recycling captured 80% of the composite fibers, thanks to a local chemical‑recycling plant.

Future Outlook: Emerging Materials and Standards

Researchers are developing ultra‑light, high‑stiffness materials like graphene‑reinforced polymers and magnesium alloys. Early LCA data suggest potential carbon reductions of up to 40% compared with conventional steel, provided recycling pathways mature.

Standard bodies such as ISO and ASTM are updating guidelines to include stiffness‑related environmental metrics. The upcoming ISO14044‑E (Environmental impact of material stiffness) will require manufacturers to report elastic modulus alongside embodied energy, making sustainability decisions more data‑driven.

Key Takeaways

- Stiffness directly influences material quantity, manufacturing energy, and end‑of‑life recyclability.

- High‑stiffness metals are recyclable but energy‑intensive; high‑stiffness composites offer weight savings but face recycling challenges.

- Life‑cycle assessment is essential for weighing upfront emissions against use‑phase benefits.

- Designing for a circular economy means choosing recyclable stiff materials, optimizing geometry, and planning for modular reuse.

- Emerging standards will soon make stiffness‑environment metrics mandatory, pushing the industry toward greener choices.

Frequently Asked Questions

How does material stiffness affect a product's carbon footprint?

Stiffness determines how much material you need to meet load requirements. Higher stiffness can mean thinner, lighter parts, reducing material mass and associated emissions. However, achieving that stiffness often requires energy‑intensive processes (e.g., alloying, fiber reinforcement). The net carbon impact therefore depends on the balance between material savings and manufacturing energy, which LCA tools can quantify.

Are stiff polymers recyclable?

It varies. Thermoplastic polymers (e.g., PA‑6, PEKK) can be remelted and recycled while maintaining stiffness, making them suitable for circular designs. Thermoset resins, common in high‑stiffness composites, cure into a permanent network and cannot be remelted, limiting recycling to costly chemical methods. Emerging recyclable thermosets aim to close this gap.

What role does elastic modulus play in sustainable design?

Elastic modulus quantifies stiffness. Designers use it to size components precisely-higher modulus means you can use less material to achieve the same rigidity. Accurate modulus data enables lightweighting, which lowers material consumption and operational energy, key pillars of sustainability.

Can high‑stiffness materials be used in a circular economy?

Yes, but it requires careful selection. Metals are inherently recyclable, and recyclable thermoplastic composites are emerging as viable high‑stiffness options. The design must also consider modularity and ease of disassembly so that stiff components can be recovered and reused at the end of a product's life.

What standards should I follow when reporting stiffness‑related environmental data?

Watch for the upcoming ISO14044‑E, which will require reporting both elastic modulus and embodied energy. Until then, combine ISO14040/14044 life‑cycle assessment guidelines with ASTM standards for mechanical testing (e.g., ASTME111 for modulus) to provide a transparent, comparable dataset.

RaeLyn Boothe

September 26, 2025 AT 22:01Stiffness is a double‑edged sword for sustainability.

Fatima Sami

September 27, 2025 AT 21:06The elastic modulus is measured in gigapascals (GPa), not just “high” or “low”. In the article, steel’s modulus is correctly stated as approximately 200 GPa, whereas polypropylene is about 1.5 GPa. Those numbers directly drive the stress‑strain calculations engineers perform when sizing components.

Arjun Santhosh

September 29, 2025 AT 00:53Nice rundown on stiffness and sustainability. I especially liked the point about modular design-makes disassembly far easier. The trade‑off between material mass and stiffness is something we see daily in the shop. Keep pushing for those lightweight solutions, even if my notes sometimes have a typo or two.

Stephanie Jones

September 30, 2025 AT 04:40Thinking about stiffness feels like contemplating rigidity in our own habits-too much can break us, too little leaves us limp. The article reminds us that material choices echo the balance we seek in life. Each kilogram saved is a small act of humility toward the planet. Yet the energy spent to achieve that stiffness can betray our intentions if we’re not careful. In the end, the true measure is how responsibly we close the loop.

Nathan Hamer

October 1, 2025 AT 08:26Wow-what a deep dive into the world of elastic modulus! 🌟 The interplay between carbon‑fiber weight savings and upfront CO₂ footprints is nothing short of a drama worthy of the silver screen!!! 🚀 Designers truly wield stiffness like a super‑power, sculpting lighter, faster machines while battling hidden energy costs. Keep the research rolling; the future of sustainable engineering looks brighter than ever!!! 😊

Tom Smith

October 2, 2025 AT 12:13Impressive list of numbers, but let’s not pretend that a higher modulus magically solves every environmental puzzle. While steel’s recyclability is indeed high, the energy required for alloying and heat‑treatment still drags the life‑cycle impact upward. Conversely, those fancy composites boast low weight yet hide behind complex chemical recycling schemes that many facilities simply cannot afford. So, choose wisely-big claims need big data to back them up.

Kyah Chan

October 3, 2025 AT 16:00The exposition suffers from an overreliance on anecdotal case studies, thereby compromising its scientific rigor. Moreover, the juxtaposition of disparate units-gigapascals versus megajoules per kilogram-without proper normalization undermines comparative analysis. One must also critique the omission of end‑of‑life economic assessments, which are indispensable for a holistic sustainability evaluation. In summary, the manuscript requires substantial methodological refinement before it can be deemed a credible contribution to the field.

Ira Andani Agustianingrum

October 4, 2025 AT 19:46Great job breaking down such a complex topic! I love how you highlighted both the upside of high‑stiffness materials and the recycling hurdles they bring. It’s clear that designers have to juggle performance with environmental stewardship-a real balancing act. If you ever need a sounding board for new material ideas, just give me a shout.

James Higdon

October 5, 2025 AT 23:33The ethical imperative to reduce embodied carbon cannot be overstated, and this discussion aptly underscores that responsibility. Selecting materials based solely on performance, without regard for life‑cycle emissions, would be an abdication of our duty to future generations. Therefore, integrating stiffness considerations within a circular‑economy framework is not merely advantageous-it is obligatory. Industry stakeholders must adopt these principles lest we perpetuate avoidable ecological damage.

Wanda Smith

October 7, 2025 AT 03:20Do you ever wonder why the push for carbon‑fiber keeps getting louder, even as the recycling infrastructure remains woefully inadequate? It feels like a coordinated effort to shift the blame onto consumers while the true profit lies in the rare‑earth supply chain that never sees the daylight. The article mentions upcoming standards, yet history shows they’re often delayed to protect entrenched interests. Stay vigilant; the narrative is being crafted for those who profit from our ignorance.

Bridget Jonesberg

October 8, 2025 AT 07:06One cannot discuss material stiffness without first acknowledging its philosophical resonance with the very notion of permanence in a transient world. The elastic modulus, that cold numerical sentinel of resistance, stands as a metaphor for society's yearning to impose order upon chaos. When engineers select a high‑modulus alloy they are, in effect, subscribing to a doctrine of durability that transcends mere function. Yet this pursuit of rigidity is frequently at odds with the fluidity required for true circularity, a paradox that has occupied scholars for decades. The article’s table, replete with gigapascal figures, subtly illustrates how quantitative dominance can eclipse qualitative nuance. In practice, the energy expended to achieve those lofty modulus values often manifests as hidden emissions that escape casual inspection. Moreover, the recycling rates cited betray an unsettling reality: while metals circulate with admirable efficiency, the very composites that promise weight savings become inert relics upon disposal. This discord between aspiration and outcome mirrors the broader human condition, where ambition frequently outpaces responsibility. It is therefore essential to interrogate not just the numbers, but the underlying assumptions that grant them authority. The life‑cycle assessment methodology, praised within the text, offers a veneer of objectivity while merely aggregating disparate metrics into a single narrative. Such aggregation risks obscuring the nuanced trade‑offs that define sustainable design. The emerging standards, like the forthcoming ISO14044‑E, may provide the scaffolding needed to reconcile stiffness with environmental stewardship, but only if they incorporate transparent, verifiable data. Until then, practitioners are left navigating a labyrinth of partial truths, balancing stiffness against recyclability with the dexterity of a tightrope walker. In summation, the dialogue surrounding material stiffness must evolve beyond dichotomous judgments and embrace a more holistic, interdisciplinary perspective. Only then can the industry hope to reconcile the relentless quest for performance with the inexorable demand for planetary health.

Marvin Powers

October 9, 2025 AT 10:53Bravo on that marathon of thoughts; you’ve certainly painted the canvas in vivid, if overwhelming, strokes. While I admire the grandiloquence, let’s not forget that engineers need bite‑size guidelines, not just philosophical treatises. The upcoming ISO standard will likely trim the excess rhetoric and hand us a practical checklist. Until then, we can keep debating in comment sections while the real world waits for actionable solutions.